Pipe Welder Resume Examples for Texas Jobs

Key Insight

Texas pipe welder resumes must surface API 1104 and 6G certifications immediately. These are the first credentials Houston-area and Permian Basin employers scan for before reviewing experience.

| Resume Comparison by Experience Level |

|---|

| Resume Level | Best For | Key Certifications | Pay Range |

|---|

| Entry-Level | Recent grads, career changers | 6G, API 1104 | $45K-$65K |

| Experienced | Production welders | 6G, API 1104, TWIC, ASME IX | $70K-$105K |

| Lead/Foreman | Supervisors, QC track | All + CWI in progress | $95K-$130K+ |

The fastest way to understand what Texas employers want is to see real examples. The resumes below cover entry-level, experienced, and lead pipe welder roles, showing how to position certifications, quantify production, and align language to Texas hiring expectations.

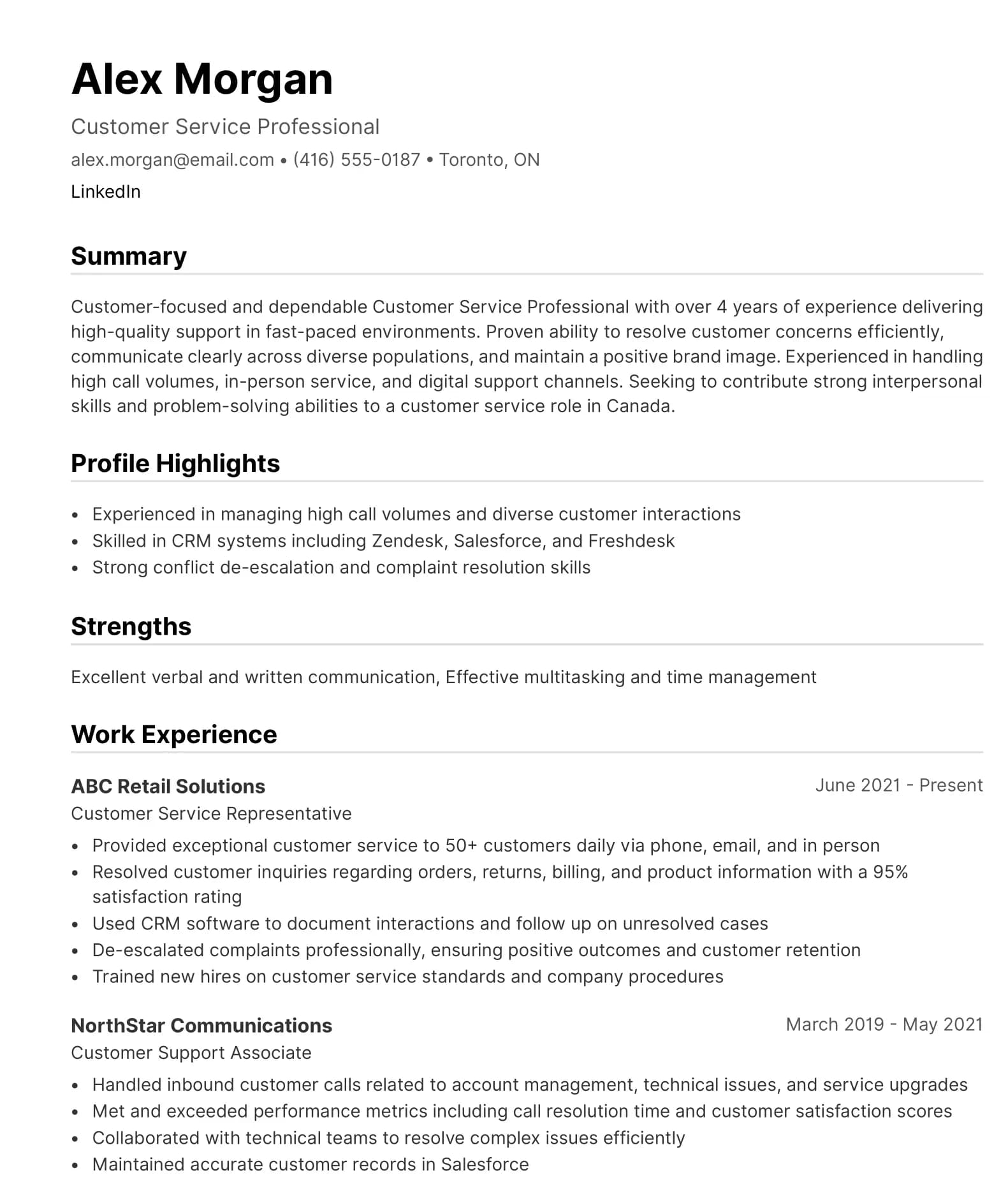

Entry-Level Pipe Welder Resume (Recent Certification)MICHAEL RODRIGUEZ

Entry-Level Pipe Welder | 6G Certified | Available for Texas Travel

Houston, TX 77002 | (713) 555-0147 | m.rodriguez.welder@yotruemail.com

CERTIFICATIONS

- 6G Pipe Welding Certification (Carbon Steel, 2"-6" Schedule 40, SMAW) - December 2025

- API 1104 Pipe Welding Qualification (TIG root, stick fill/cap) - December 2025

- OSHA 10-Hour Construction Safety - November 2025

- AWS D1.1 Structural Steel (3G/4G Plate) - October 2025

PROFESSIONAL SUMMARY Entry-level pipe welder with fresh 6G certification and API 1104 qualification seeking helper or junior welder position with Texas pipeline contractor or industrial facility. Trained in TIG root pass technique on carbon steel pipe 2"-6", stick welding fill and cap with E6010 and E7018. Achieved 95% X-ray pass rate during certification testing. Available for immediate travel throughout Texas oil and gas regions including Permian Basin, Eagle Ford, and Gulf Coast projects.

SKILLS & QUALIFICATIONS

- Welding Processes: GTAW (TIG) root pass on pipe, SMAW (stick) fill and cap, GMAW (MIG) plate welding

- Pipe Experience: 2"-6" Schedule 40 carbon steel pipe, open root TIG, backing ring applications

- Welding Positions: 6G (45-degree fixed pipe), 5G (horizontal fixed), 2G (horizontal rolled)

- Code Standards: API 1104 pipeline welding, AWS D1.1 structural steel

- Equipment: Miller Dynasty TIG machines, Lincoln Electric stick welders, oxy-acetylene cutting torch

- Blueprint Reading: Weld symbols, pipe isometric drawings, weld procedure specifications (WPS)

- Inspection Knowledge: Visual weld inspection criteria, X-ray acceptance standards, UT testing basics

- Safety: Confined space entry, hot work permits, fall protection, PPE compliance

WELDING EDUCATION & TRAINING Pipe Welding Specialist Program

Texas Gulf Coast Trades Institute, Houston, TX

August 2025 - December 2025

- Completed 640-hour intensive pipe welding program with emphasis on API 1104 standards

- Trained on 2" through 6" carbon steel pipe in all positions (2G, 5G, 6G)

- Mastered TIG root pass technique with E6010 hot pass and E7018 fill/cap procedures

- Achieved 95% first-time X-ray pass rate on certification test coupons (19 of 20 welds passed)

- Practiced pipe fitting, alignment, and tack welding under certified welding inspector supervision

- Completed 120 hours of hands-on industrial pipe fabrication projects

Certifications Earned:

- 6G Unlimited Thickness Pipe Certification (qualifies for all positions, all diameters)

- API 1104 Open Root TIG + Stick Combination Procedure

- Passed bend tests and X-ray examination per AWS/API standards

RELEVANT WORK EXPERIENCE Welder Helper

ABC Fabrication & Steel, Houston, TX

January 2024 - July 2025

- Assisted certified pipe welders with fit-up, alignment, and tack welding on structural and pipe projects

- Prepared pipe ends using grinders and beveling tools to achieve proper weld joint geometry

- Set up welding equipment including TIG and stick machines, gas regulators, and lead connections

- Performed grinding, wire brushing, and weld cleaning to prepare for inspection

- Operated overhead crane and forklift to position pipe sections and structural steel (OSHA certified)

- Maintained clean and organized work area in compliance with 5S workplace standards

Warehouse Associate

Industrial Supply Company, Houston, TX

March 2022 - December 2023

- Operated forklifts and pallet jacks to move heavy materials (up to 4,000 lbs)

- Read and interpreted shipping documents, material specifications, and inventory lists

- Worked safely in fast-paced industrial environment with strict safety protocols

ADDITIONAL INFORMATION

- Travel: Willing to travel throughout Texas for pipeline and industrial projects

- Physical: Able to lift 50+ lbs, work in confined spaces, and weld in all positions for extended periods

- Availability: Immediately available for day shift, night shift, or rotating schedules

- Transportation: Valid Texas driver's license, reliable personal vehicle

- References: Welding instructor and welding inspector references available upon request

Recent welding school graduates, career changers with fresh certifications, helpers stepping up to welder positions in Texas

Why This Resume Works for Entry-Level Texas Pipe Welders:

Certifications listed first - Texas employers scan for 6G and API 1104 before reading anything else

95% X-ray pass rate quantified - Demonstrates quality even without field experience

Travel availability stated clearly - Texas pipeline work requires mobility across regions

TIG root pass emphasized - Critical skill for Texas pipeline and industrial work

Helper experience shown - Proves familiarity with industrial work environment

Specific equipment named - Miller, Lincoln brands common in Texas shops

Experienced Pipe Welder Resume (5 Years Production Welding)JAMES MITCHELL

Certified Pipe Welder | API 1104 & ASME IX | 6G Qualified

Corpus Christi, TX 78401 | (361) 555-0293 | jm.welder@yotruemail.com

PROFESSIONAL SUMMARY Certified pipe welder with 5+ years production experience on oil and gas pipelines, refinery turnarounds, and industrial plant construction throughout Texas Gulf Coast region. Qualified to API 1104 and ASME Section IX standards with proven track record welding 150+ pipe joints monthly while maintaining 98% first-time X-ray pass rate. Specialized in TIG root pass on carbon steel and stainless pipe 2"-24" diameter in all positions. TWIC card holder with current offshore facility access clearance.

CERTIFICATIONS & QUALIFICATIONS

- 6G Pipe Certification: Carbon steel unlimited thickness (2" through 24"+ diameter)

- API 1104: TIG root + stick fill/cap on carbon steel pipe, all positions

- ASME Section IX: Stainless steel pipe (304/316L) 2"-12", TIG/stick combination

- TWIC Card: Transportation Worker Identification Credential (valid through 2027)

- OSHA 30-Hour Construction: Fall protection, confined space, hazard communication

- Fit Testing: Current respirator medical clearance and fit test

- First Aid/CPR: American Red Cross certified

CORE COMPETENCIES

- Welding Processes: GTAW (TIG) root pass, SMAW (stick) fill and cap, orbital TIG systems

- Materials: Carbon steel (A106 Grade B), stainless steel (304, 316L, 321), chrome-moly

- Pipe Sizes: 2" Schedule 40 through 24" heavy wall, shop and field fabrication

- Positions: 6G fixed, 5G horizontal fixed, 2G rolled, restricted access welding

- Testing: 100% X-ray inspection, ultrasonic testing, hydrostatic pressure testing

- Codes: API 1104 (pipeline), ASME B31.3 (process piping), ASME Section IX (boilers/pressure vessels)

- Tools: Pipe bevelers, portable welding machines, orbital weld heads, pipe alignment clamps

PROFESSIONAL EXPERIENCE

Pipe Welder

Gulf Coast Pipeline Contractors, Corpus Christi, TX

March 2023 - Present

- Weld 150-180 pipe joints monthly on natural gas transmission pipelines (12"-20" diameter) across South Texas

- Perform TIG root passes with E6010 hot pass and E7018 fill/cap per API 1104 procedures

- Maintain 98% first-time X-ray pass rate on production welding (zero repair rate last 8 months)

- Complete tie-ins and hot taps on active natural gas lines under strict safety protocols

- Travel to project sites throughout Texas Gulf Coast, Permian Basin, and Eagle Ford regions

- Communicate daily with CWI (Certified Welding Inspector) and address any weld quality concerns

- Mentor helper welders on pipe fit-up, alignment techniques, and proper tack weld placement

Key Accomplishments:

- Achieved zero safety incidents over 2,500 work hours on high-pressure gas pipeline projects

- Selected for critical tie-in welds on $15M pipeline expansion due to consistent quality record

- Completed emergency pipeline repair ahead of schedule during Hurricane Harvey recovery (2023)

Pipe Welder

Refinery Services Inc., Beaumont, TX

June 2021 - February 2023

- Welded process piping on refinery turnarounds (2"-12" stainless and carbon steel)

- Performed ASME B31.3 code welding on heat exchangers, pressure vessels, and reactor piping

- Executed confined space welding on vessel internals and restricted-access pipe runs

- Read and interpreted P&IDs, isometric drawings, and weld procedure specifications (WPS)

- Coordinated with pipefitters, QC inspectors, and turnaround supervisors to meet critical deadlines

- Worked rotating 12-hour shifts during scheduled plant outages (14/7 and 21/7 rotations)

Key Accomplishments:

- Completed 45-day turnaround project with zero weld rejections on 200+ TIG root passes

- Earned "Craftsman of the Quarter" recognition for quality and productivity (Q3 2022)

- Cross-trained on orbital TIG welding systems for pharmaceutical-grade stainless piping

Welder / Pipefitter Helper

Texas Industrial Welding, Houston, TX

January 2020 - May 2021

- Assisted journeyman welders with pipe fitting, alignment, and tack welding on industrial projects

- Operated beveling machines, grinders, and cutting torches to prepare pipe ends for welding

- Learned pipe fabrication techniques including rolling offsets, branch connections, and flange alignment

- Completed internal welding certification program and earned first 6G qualification (May 2020)

EDUCATION & TRAINING Industrial Pipe Welding Certificate

San Jacinto College, Pasadena, TX - 2019

High School Diploma

Port Arthur High School, Port Arthur, TX - 2018

ADDITIONAL INFORMATION

- Production Metrics: Consistently weld 25-30 joints per week on mainline pipeline construction

- Travel: Experienced with out-of-town projects, per diem, and temporary job site housing

- Equipment: Own Miller Bobcat 250 portable welder/generator (roadworthy rig)

- Drug Screening: Current and willing to submit to pre-employment and random testing

- Background: Clean MVR, no safety violations, able to pass industry background checks

Welders with 3-7 years field experience, production pipeline welders, those seeking higher-paying Texas refinery or LNG facility work

Why This Resume Works for Experienced Texas Pipe Welders:

Production numbers quantified - "150-180 joints monthly" and "98% X-ray pass rate" prove capability

TWIC card mentioned - Essential for Gulf Coast offshore and facility access

Company names included - Shows experience with recognized Texas contractors

Regional knowledge demonstrated - Permian Basin, Eagle Ford, Gulf Coast all mentioned

Zero safety incidents highlighted - Critical for Texas oil/gas industry

Turnaround experience shown - Refinery work is major Texas pipe welding market

Lead Pipe Welder Resume / Foreman (12+ Years)ROBERT CLAYTON

Lead Pipe Welder & Welding Foreman | API 1104 & AWS CWI Track

Midland, TX 79701 | (432) 555-0891 | rc.lead@yotruemail.com

LinkedIn: linkedin.com/in/robertclayton-welder

EXECUTIVE SUMMARY Lead pipe welder and field supervisor with 12+ years managing crews on major Texas pipeline projects including cross-country transmission lines, gathering systems, and industrial plant construction. Proven track record leading 8-15 person welding crews while maintaining project schedules, quality standards, and zero-incident safety records. Expert in API 1104 and ASME codes with multiple process certifications (TIG, stick, MIG, orbital). Currently pursuing AWS Certified Welding Inspector (CWI) credential to transition into quality control and project management roles.

LEADERSHIP & MANAGEMENT EXPERIENCE

Lead Pipe Welder / Field Supervisor

Lone Star Pipeline Construction, Midland, TX

April 2019 - Present

Crew Leadership:

- Supervise 8-12 pipe welders and helpers on natural gas transmission pipeline projects (16"-36" diameter)

- Plan daily welding operations, assign welds based on crew qualifications, and monitor production rates

- Conduct pre-shift safety meetings, JSA (Job Safety Analysis) reviews, and toolbox talks

- Communicate with project managers, CWI inspectors, and client representatives on quality and schedule

Technical Responsibilities:

- Weld critical tie-ins, road bores, and difficult-access joints requiring advanced skills

- Review weld procedure specifications (WPS) and ensure crew compliance with API 1104 standards

- Troubleshoot welding quality issues including porosity, incomplete fusion, and cracking

- Perform visual weld inspection and prepare welds for X-ray or UT examination

- Maintain welding equipment including portable machines, leads, ground clamps, and consumables

Key Accomplishments:

- Led crew completing 2.5-mile natural gas pipeline expansion 3 weeks ahead of schedule (2024)

- Maintained 97% first-time X-ray pass rate across 1,200+ production welds over 18-month project

- Achieved zero OSHA recordable incidents over 15,000 crew work hours (2022-2024)

- Reduced weld repair rate from 8% to 2% through improved crew training and quality focus

- Mentored 6 helper welders who successfully obtained 6G certifications during employment

Senior Pipe Welder

Permian Basin Welding Services, Odessa, TX

March 2015 - March 2019

- Welded oil and gas gathering systems, saltwater disposal lines, and production facilities

- Performed all-position welding on 2"-12" carbon steel pipe in remote West Texas locations

- Completed high-priority welds on active well sites with strict safety and environmental protocols

- Coordinated with directional drilling crews on pipeline crossings and road bores

- Trained new hires on company welding procedures, equipment operation, and safety requirements

Key Accomplishments:

- Promoted to senior welder after 18 months based on consistent quality and reliability

- Selected for critical welds on high-pressure H2S service pipelines (sour gas applications)

- Earned company safety award 3 consecutive years (2016, 2017, 2018)

Pipe Welder

Multiple Contractors (Houston, Corpus Christi, Beaumont areas)

January 2013 - February 2015

- Gained diverse experience on refinery turnarounds, LNG facility construction, and offshore platform work

- Welded carbon steel, stainless steel, and chrome-moly pipe in shop and field environments

- Developed multi-process skills including TIG, stick, MIG, and flux-cored arc welding

- Worked extensively with CWI inspectors, learning code interpretation and quality standards

CERTIFICATIONS & QUALIFICATIONS

Current Welding Certifications:

- 6G Pipe Welder (Carbon Steel, Unlimited Thickness)

- API 1104 Multiple Procedures (TIG root + stick, stick only, orbital TIG)

- ASME Section IX (Stainless steel 304/316L, chrome-moly P5 material)

- Orbital TIG Operator (2"-4" automatic pipe welding systems)

Professional Development:

- AWS Certified Welding Inspector (CWI) - Currently studying, exam scheduled March 2026

- OSHA 30-Hour Construction Safety Certification

- Confined Space Entry Supervisor

- Competent Person: Fall Protection & Scaffolding

- First Aid/CPR/AED Instructor

Safety & Compliance:

- TWIC Card (valid through 2028)

- SafeLand USA & PEC SafeGulf Training

- H2S Alive & Well Control Awareness

- DOT Pipeline Safety Regulations (Part 192, Part 195)

TECHNICAL SKILLS

Welding Expertise:

- Processes: GTAW, SMAW, GMAW, FCAW, orbital TIG, oxy-fuel cutting

- Materials: Carbon steel (all grades), stainless (300 series), chrome-moly (P5, P11, P22), nickel alloys

- Pipe Range: 2" Schedule 40 through 42" heavy wall transmission pipe

- Codes: API 1104, ASME B31.3, B31.4, B31.8, ASME Section IX, AWS D1.1

Inspection & Quality:

- Visual weld inspection per AWS and API standards

- Understanding of RT (X-ray), UT (ultrasonic), MT (magnetic particle) testing methods

- WPS/PQR review and interpretation

- Weld defect analysis and corrective action planning

Project Management:

- Crew scheduling and work planning

- Material and consumable inventory management

- Daily production reporting and documentation

- Client communication and coordination

EDUCATION

Associate of Applied Science - Welding Technology

Odessa College, Odessa, TX - 2014

Certifications & Continuing Education:

- AWS CWI Preparation Seminar (in progress)

- Leadership in Construction Safety (Texas A&M Engineering Extension Service)

- Pipeline Welding Advanced Techniques (American Welding Society)

PROFESSIONAL AFFILIATIONS

- American Welding Society (AWS) - Member since 2015

- Pipeline Contractors Association - Associate Member

EQUIPMENT & CAPABILITIES

- Own complete welding rig: 2019 Ford F-350 with Miller Big Blue 500 X welder/generator

- Fully equipped with TIG torch, stick stingers, ground clamps, and safety equipment

- Current DOT inspection, commercial liability insurance, roadworthy for travel

REFERENCES Available upon request - Include project managers, welding inspectors, and safety coordinators from recent Texas pipeline projects

Lead welders, welding foremen, those seeking supervisor or QC inspector track positions at major Texas contracto

Why This Resume Works for Lead Pipe Welder / Foreman Roles:

Leadership quantified - "8-12 person crews" and "15,000 work hours" show scale

Safety record emphasized - Zero incidents critical for supervisor positions

CWI pursuit mentioned - Shows career progression toward inspection/QC roles

Project completion metrics - "3 weeks ahead of schedule" demonstrates management capability

Training/mentoring highlighted - "6 helper welders certified" proves leadership

Equipment ownership noted - Own welding rig = serious professional in Texas market

Key Insight

If this feels overwhelming, upload your resume and let the system flag what actually matters for Texas jobs.

ATS-Optimized resumes That Meet Employer Standards

Our AI-powered scoring system helps organizations assess and standardize resume quality at scale. ATS-compliant templates support consistent formatting, keyword alignment, and interview readiness across cohorts.

Essential Keywords for Texas Pipe Welder Resumes

Employers scan resumes for specific certification, process, and production terms. These keywords should appear naturally in your summary, certifications, and work experience to pass ATS screening and human review.

Certification Keywords (Highest Priority)

6G certification unlimited thickness

API 1104 pipe welding qualification

ASME Section IX pressure vessel

TWIC card valid current

OSHA 30 construction safety

Why these matter: 6G and API 1104 are baseline requirements for Texas pipeline and refinery work. TWIC is required for Gulf Coast sites. ASME Section IX applies to refineries and pressure vessels.

Process and Technique Keywords

Texas-specific context:

- "TIG root pass" is standard procedure for mainline pipeline work

- "E6010 and E7018" electrodes are industry standard for Texas pipeline projects

- "X-ray quality" indicates you understand inspection standards

- "Orbital TIG" is increasingly common for pharmaceutical and food-grade piping

If you’re unsure which keywords matter most, Yotru’s resume builder automatically highlights role-specific certifications, process terms, and production metrics as you build, helping ensure your resume clears ATS screening and reaches human reviewers.

Include brand names common in Texas welding industry:

- Miller Dynasty TIG machines

- Lincoln Electric Ranger portable welders

- Miller Bobcat welder/generator combos

- Beveling machines (H&M, Tri-Tool)

- Pipe alignment clamps and fit-up tools

Measurement and Production Keywords

Quantify your work with industry standards:

- "Inches welded per day" (typical: 20-40 inches for 6" pipe)

- "Joints completed per week" (typical: 25-35 for mainline work)

- "X-ray pass rate percentage" (target: 95%+ first-time pass)

- "Zero defect" or "zero repair" records

- "Production welding" vs. "critical welds" or "tie-ins"

Safety and Compliance Terms

Place your highest-value keywords (6G, API 1104, TWIC) in the first three lines of your resume. Texas employers scan fast and won’t read further if certifications don’t match.

Texas Pipe Welder Certifications

Employers focus on certifications that prove production readiness and safety compliance.

Must-Have

- 6G Pipe Certification (Unlimited Thickness): The baseline for most Texas pipe welding jobs. Covers all positions and pipe sizes. Employers treat 6G as proof you can weld at production level without additional position testing.

- API 1104 (Pipeline Welding): Required for oil and gas pipeline work across Texas, including Permian Basin, Eagle Ford, and Gulf Coast projects. Certifications must match the employer’s specific WPS, or retesting is required.

High-Value Add-Ons

- TWIC Card: Required for refineries, ports, LNG facilities, and offshore access. Significantly increases job access along the Gulf Coast.

- ASME Section IX: Needed for refinery turnarounds, chemical plants, power generation, and pressure vessel work. Common materials include carbon steel, stainless, and chrome-moly.

- OSHA 30-Hour Construction: Preferred by major Texas contractors. Signals strong safety knowledge and readiness for large-scale industrial sites.

Certifications to Skip (Unless Required)

- Specialty certs without matching experience

- Exotic materials with no active demand

- Structural-only certs if targeting pipe work

- Advanced niche certs before securing employment

Texas employers hire based on production readiness. Focus on certifications that prove you can weld safely, pass X-ray, and perform under real jobsite conditions.

How to Position Your Experience for Texas Markets

Texas pipe welding work divides into three distinct regional markets, each with different priorities and resume positioning strategies.

The same pipe welder can be qualified in one Texas market and ignored in another. Resume alignment matters as much as certification.

Houston Area: Refineries & Petrochemical Plants

What they screen for first: Safety, code compliance, and turnaround experience

Resume must show:

- TWIC card and ASME Section IX

- Turnaround or refinery unit experience

- Stainless or chrome-moly TIG work

Common miss: Strong welding background but no refinery keywords

Gulf Coast: Offshore & LNG Facilities

What they screen for first: Access credentials and offshore readiness

Resume must show:

- TWIC card (non-negotiable)

- Offshore or marine environment experience

- Rotation schedules and per diem readiness

Common miss: Good pipe welders blocked by missing access or offshore context

Permian Basin: Pipeline Construction

What they screen for first: Production speed and volume

Resume must show:

- 6G unlimited + API 1104

- Mainline or gathering system work

- Weld volume and X-ray pass rate

Common miss: No production metrics or unclear rig ownership

Yotru automatically adjusts your resume language and keywords to match the Texas market you’re targeting.

What Texas Pipe Welding Jobs Pay

Understanding Texas pay structures helps you negotiate effectively and know whether job offers are competitive.

Pay Ranges by Experience Level

| Texas Pipe Welder Pay Ranges |

|---|

| Experience Level | Hourly Rate | Annual Equivalent (40 hrs/wk) | Annual With Overtime |

|---|

| Entry-Level (0-2 years) | $18-$26 | $37,000-$54,000 | $45,000-$65,000 |

| Experienced (3-7 years) | $28-$42 | $58,000-$87,000 | $70,000-$105,000 |

| Lead Welders / Foremen (8+ years) | $38-$52 | $79,000-$108,000 | $95,000-$130,000+ |

Regional Pay Differences

- Houston area (highest base pay): Refinery welders earn about $32–45/hour, typically in W-2 roles with benefits. Schedules are more stable with less overtime.

- Permian Basin (highest total pay): Pipeline welders earn $36–52/hour, often as 1099 contractors. Long weeks (60–70 hours) plus $100–150/day per diem drive higher total compensation.

- Corpus Christi / Gulf Coast: Offshore welders earn $35–48/hour on rotation schedules (14/7 or 21/7). Per diem and offshore bonuseUnderstanding Texas Pay Structures

- Arm pay (taxable): Your base hourly wage paid on a W-2 or 1099. Experienced pipe welders typically earn $36–42/hour.

- Truck pay (equipment): Extra pay if you supply your own rig. Usually $10–15/hour and often reported separately on a 1099.

- Per diem (tax-advantaged): Daily allowance for meals and lodging when working away from home. In Texas, typically $50–75/day if documented.

- Example weekly total: $40/hr arm pay + $12/hr truck pay × 60 hrs = $3,120, plus $360 per diem → $3,480/week (about $181k/year if sustained).

When comparing job offers, always ask about ALL compensation components. A "$38/hour job" with no per diem or truck pay may actually pay less than a "$35/hour job" that includes $12/hour truck pay and $65/day per diem.

Benefits and Overtime

- Union vs. non-union: Union roles offer higher base pay, benefits, pensions, and paid overtime. Non-union work is more common in Texas, often 1099, with flexible schedules and higher straight-time rates.

- Pipeline overtime: Pipeline jobs typically run 50–65 hours per week, with consistent overtime during active projects.

- Refinery and maintenance work: Refinery turnarounds can reach 70–84 hours per week during outages, while maintenance roles usually stay around 40–50 hours per week.

Where to Find Texas Pipe Welding Jobs

Knowing where pipe welders actually find work helps you focus your job search on channels that produce results.

- Staffing agencies: Fast placement and varied projects, but expect 1099 work, fewer benefits, less security, and agencies taking 10–20%. Common Texas agencies include Tradesmen International, HC Tradesmen Staffing, Requs, and Select Source International. Major Texas employers are Kinder Morgan, Energy Transfer, Plains All American Pipeline, and Enterprise Products Partners.

- Word of mouth: The most effective route. Many pipe welders find jobs through referrals. Stay in touch with past coworkers, join Texas welding Facebook groups, attend AWS meetings, and ask supervisors about upcoming work when a job ends.

- Walk-ins: Still effective at smaller shops. Bring a printed resume and certifications, arrive 7:00–8:00 AM, wear clean work clothes, and be ready for same-day drug testing. Focus on Houston Ship Channel, Odessa, Midland, Corpus Christi, and pipeline yards.

- Online job boards: Best options are Indeed, RigUp, LinkedIn, and company career pages. General job boards and Craigslist are usually less reliable.

Create a one-page “walking resume” with certifications, recent projects, and contact info. Yotru can generate a print-ready power resume in one page.

Common Mistakes on Welder Resumes

Avoid these errors that immediately disqualify otherwise qualified candidates.

No certifications listed first

Listing expired certifications without dates

Generic objective instead of Texas-specific summary

No quantified production metrics

Missing TWIC card when applying to Gulf Coast

Spelling errors on welding terms

Yotru’s resume builder guides you step by step to surface the right certifications, production metrics, and formatting so your resume clears ATS screening and reaches human recruiters.

Building Your Pipe Welder Resume With Yotru

Texas pipe welder resumes must prove production ability, current certifications, and safety performance. Strong resumes lead with 6G or API 1104 credentials, include X-ray pass rates and weld volume, and reflect the expectations of Texas refineries, pipelines, and offshore work.

If you want to see how your resume performs against real hiring systems, get started with your ATS score below.

ATS-Optimized resumes That Meet Employer Standards

Our AI-powered scoring system helps organizations assess and standardize resume quality at scale. ATS-compliant templates support consistent formatting, keyword alignment, and interview readiness across cohorts.